What is Pointing Methods of Pointing process of Painting

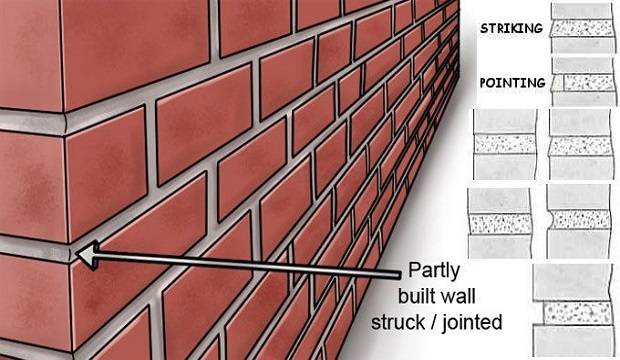

The term pointing is used to denote the finishing of mortar joints of either stone masonry or brick masonry. The joints are raked out to a depth of about 20 mm and then, these spaces are filled up by suitable mortar in the desired shape.

It is desirable to avoid pointing as far as possible. This is because pointing involves raking out of joints that are constructed with good mortar and filling the joints with mortar which, in many cases, is not sufficiently watered.

For this reason, the pointing work of the new structure should follow the masonry work in progress. The joints are thus raked out when the mortar has not set.

Mortar for pointing: The pointing is generally adopted for the finishing of exposed external walls of a structure. It is cheap in the first coat, but it requires frequent replacement.

The pointing may be carried out either in lime mortar or in cement mortar. The lime mortar consists of equal volumes of lime and sand. These two materials are carefully ground in a mortar mill.

The sand to be used for preparing lime mortar should be clean, fine, and free from any organic impurities.

The cement mortar consists of equal volumes of cement and sand. The cement should comply with standard requirements and sand should be clean, fine, and free aryl organic impurities.

The materials are thoroughly mixed in dry condition before water is added to them. The mixing of the materials is done on a water light platform and the mortar of one cement bag only is prepared at a time and this quantity of mortar is consumed within 30 minutes after adding water.

What is Pointing Work in Construction | How to do Pointing on Brickwall | How to Point a Brick Work

Method of pointing

1. The mortar of the masonry joints to be covered by pointing is raked out at least to a depth of 20 mm.

2. The dust from the masonry joints is removed by the brushes.

3. The surface is then washed with clean water and it is kept wet for a few hours.

4. The mortar is then carefully placed in the desired shape in these prepared joints. The mortar is placed in joints. The mortar is placed by a small trowel and it is slightly pressed to bring it into close contact with the old interior mortar of the joint.

5. The finished surface is well -watered for at least 3 days. if lime mortar is used and 10 days, if cement mortar is used.

Explain the process of Painting of new Woodwork & old woodwork?

The process of painting depends on the nature of the surface to be painted.

(1) New woodwork: Normally, four coats of paint are required for the new woodwork. The process of painting is carried out as follows:

1. The surface of the woodwork is prepared to receive the paint. For satisfactory working, it is necessary that the woodwork is sufficiently seasoned and it does not contain more than 15 percent moisture at the time of painting. The surface of the woodwork is thoroughly cleaned and the heads of the nails are punched to a depth of 3 mm below

the surface.

2. The surface of the woodwork is then knotted.

3. The priming coat is then applied on the surface of the new woodwork. Generally, the priming coat is applied before the woodwork is placed in position.

4. The process of stopping is then carried out.

5. The subsequent coats of paint, namely, undercoat and finishing coats are then applied on the surface. The extreme care should be taken to see that the finishing coat presents smooth and even surface and that no brush marks are seen on the finished work.

(2) Repainting old woodwork: If the paint on the old woodwork has cracked or developed blisters, it must be removed. If the surface has become greasy, it should be cleaned by rubbing down sandpaper or fine pumice stone. The old paint can also be removed by applying any one of the following three paint solvents:

1. A solution containing 2 N of caustic soda to a liter of water is prepared and used to wash the surface. The paint dissolves and the surface becomes clean.

2. A mixture consisting of one part of soda and two parts of potash is prepared and one part of quicklime is added afterwards. This mixture is applied on the surface in a hot state and allowed to stay for about 24 hours. The surface is then washed with hot water.

3. A mixture consisting of equal parts of washing soda and quicklime is brought to a paste form by adding the required quantity of water. It is applied on the surface and kept for about an hour. The surface is then washed with water.

After removing old paint from the surface, the woodwork is painted as in the case of painting on new woodwork.

Also Read This