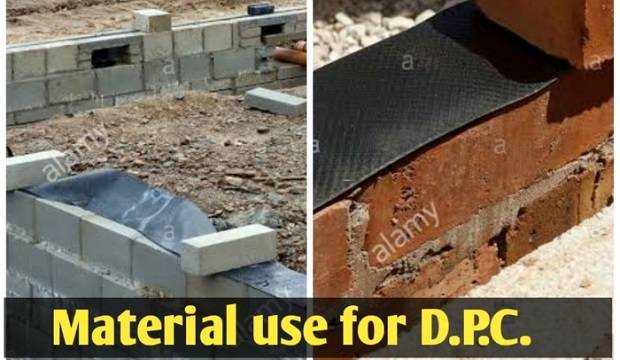

Materials used for damp proofing

Materials that are commonly used for damp-proofing:

(1) Hot bitumen: This is a flexible material and is placed on the bedding of concrete or mortar. This material should be applied with a minimum thickness of 3 mm.

(2) Mastic asphalt This is a semi-rigid material and it forms an excellent impervious layer for damp-proofing. The good asphalt is a very durable and completely waterproof material.

It can withstand only very slight distortion.

It is liable to squeeze out in very hot climates or under very heavy pressure. Experienced men of specialist firms should lay it.

(3) Bituminous felts: This is a flexible material. It is easy to lay and available in normal wall-width rolls. It is laid on a layer of cement mortar.

An overlap of 10 cm is provided at the joints and full overlap is provided at all corners.

The laps may be sealed with bitumen, if necessary.

The bitumen felt can accommodate slight movements. But it is liable to squeeze out under heavy pressure and it offers little resistance to sliding.

The material is available in rolls and it should be carefully unrolled, especially in cold weather.

(4) Metal sheets: The sheets of lead, copper, and aluminum can be used as the membranes of damp-proofing.

The lead is a flexible material. The thickness of lead sheets should be such that its weight is not less than 200 N/m2.

The lead can be dressed to complex shapes without fracture and it possesses high resistance to sliding action.

It is impervious to moisture and it does not squeeze out under ordinary pressure. It resists ordinary atmospheric corrosion.

The surfaces of lead coming on contact with lime and cement are likely to be corroded and hence, the metal should be protected by a coating it bitumen or of bitumen paint of high consistency.

Copper is a flexible material. It possesses higher tensile strength than that of lead.

It is impervious to moisture and it does not squeeze out under ordinary pressure. It possesses high resistance to sliding action.

The external walls, especially of stones, are likely to be stained when a damp-proof course of copper is adopted.

The surfaces of copper coming in contact with mortars are likely to be affected. But for normal use, the metal does not require any protective coating.

The aluminum sheets can also be used for damp-proofing. But they should be protected with a layer of bitumen.

(5) Combination of sheets and felts: A lead foil is sandwiched between asphalt or bituminous felt. This is known as the lead core and it is found to be economical, durable, and efficient.

(6) Stones: The two courses of sound and dense stones such as granites, slates, etc. laid in cement mortar with vertical breaking joints can work as an effective damp-proofing course.

The stones should extend for the full width of the wall. Sometimes, the stones can be fixed, as in the case of roof surfaces, on the exposed faces of the wall, etc.

Materials Used for DPC

(7) Bricks: The dense bricks, absorbing water less than 4.50% of their weight, can be used for damp-proofing at places where the dampness is not excessive.

The joints are kept open. Such bricks are widely used when a damp-proofing course is to be inserted in an existing wall.

(8) Mortar: The mortar to be used for bedding layers can be prepared by mixing 1 part of cement and 3 parts of sand by volume.

A small quantity of lime is added to increase the workability. For plastering work, the water-proof mortar can be prepared.

It is prepared by mixing 1 part of cement, 2 parts of sand, and pulverized alum at the rate of 120 N per m³ of sand.

In the water to be used, 0.75 N of soft soap is dissolved per liter of water and this soap water is then added to the dry mix.

The mortar thus prepared is used to plaster the surfaces. Alternatively, some patented water-proofing materials such as Pudlo, Cido, Dempro, etc. may be added to the cement mortar.

(9) Cement concrete: A cement concrete layer in the proportion of 1: 2: 4 is generally provided at the plinth level to work as a damp-proofing course.

The depth of the cement concrete layer varies from 40 mm to 15 cm. It stops the rise to water by capillary action and it is found to be effective at places where the damp is not excessive.

Also Read This