Write short note on the pretreatment of industrial wastes

Industrial wastes mainly consists of the following:

1. effluents obtained from various industrial processes, Front

2. industries floor washings bojpoloid no bed dosenauber of robusai

3. condensate water

4. sanitary and faecal waste

It is always not necessary to treat the entire industry waste. Some in plant measures may be adopted to reduce or even eliminate the objectionable matter. Following are the common measures used for industries waste pre treatments:

1. Use of soft detergents instead of hard detergents for eliminating the foam nuisance. This is known as ‘process change’.

2. Recovery of silver from photographic wastes, which provides a primary treatment. It is known as recovery of material.

3 Reuse of water in industrial processes, such as collecting cooling waters from boilers, eliminating its heat and reusing it.

4. Mixing of acidic and alkaline wastes together, for neutralizing each other and making the mixture more nearer to the normal value of pH. This process is known as mixing of trade wastes.

The industrial wastes are usually treated by the following processes:

1. The suspended solids are removed by screening or settling tanks

2. Oil, grease and fats are removed by floatation and skimming. This process can be aided by chemical treatment if necessary.

3. Colloidal matter is removed by floatation with coagulation and electrolytes followed by sedimentation and filtration

4. excessive alkalinity and acidity is removed by adding chemicals or mixing acidic waste with alkaline waste or vice-versa

5. Re oxygenation of wastes are done by aeration

6. De colorization of waste is done by chemical treatment with sedimentation or filtration or both.

What are the tolerance limit for industrial effluent discharged into public sewers?

According to IS: 3306-1965, the tolerance limit for industrial effluents discharged into public sewer are as follows:

1. its pH-value should be between 5.5 to 9.0

2. 5day BOD at 20°C should not exceed 500mg/l.

3. lead, copper and zinc should not exceed 1.0.3.0 and 15mg/l respectively,

4. effluent temperature should not exceed 45°C

5. quantity of suspended solids should not exceed 600mg

6. Chromium, nickel and cyanide should not exceed 2% each

7. effluent containing solids such as straw, plastic, wood, paint residue, gross solid from cannery wastes, cinder, ash, sand, tar, rag, hair, metal shavings, garbage, broken glass etc. should not be discharged into public sewers

8. phenolic compounds, sulphates and total inorganic dissolved solids should not exceed 5, 1000 and 2100 mg/l respectively

9. chloride and boron should not exceed 600 and 2mg/l respectively

What do you understand by acclimatization in biological treatment of industrial waste?

Biological treatment of industrial waste waters is necessary, when they contain large quantities of biodegradable substances. Such biological treatment may be used either with or without acclimatization.

Acclimatization consists of the gradual exposure of the wastewater in increasing concentration to the seed or initial micro biological population under a controlled condition.

Most of the waste water do not contain sufficient nutrients for microbiological growth, and hence nutrients like Burea (containing nitrogen), super phosphates (containing phosphorus) etc. may E have to be added to the reactors.

For balanced growth of micro organisms in a biological treatment reactor, the ratio of BOD: nitrogen: Phosphorus should be SEE 100:5: 1 for aerobic systems, and 100:2.5: 0.5for anaerobic systems.

Industrial wastewater Treatment Lecture || Environmental Engineering ||

Discuss the various chemical treatment processes used for the treatment of industrial waste water.

The chemical treatment is used to recover the dissolved organic matter from the waste water, and may consists of one or more of the following processes:

1. Reverse Osmosis or hyper filtration: The waste water containing dissolved salts are filtered through semi permeable membranes at a pressure higher than the osmotic pressure. Such a treatment requires pre treatments like a) activated So carbon adsorption; or b)chemical precipitation followed by some kind of filtration.

2. Electro dialysis: In electro dialysis dissolved salts from waste water are separated by passing an electric current through the waste water tank. This treatment also requires some pre treatment as is required in reverse osmosis process.

3. Chemical Oxidation: In chemical oxidation, chemicals like chlorine and ozone are used to reduce substances like ammonia and cyanide, etc. from the waste water, in addition to reducing BOD load on biological treatments.

4. Chemical coagulation: This is used in treating raw water supplies, and helps in sedimentation of unsettleable micro and colloidal impurities, which get absorbed in the gelatinous flocs, formed by the chemical reactions between coagulants, or between the coagulant and the alkalies present in raw water.

5. Adsorption: Adsorption is used to remove non biodegradable organics (like synthetic detergents), color and odour from waste water. The process involves passing the pre treated waste water through the beds of activated carbon.

6. Deionization: Deionization involves passage of waste water through the beds of synthetic ion exchange resins, where some undesirable cations and anions of the waste water get exchanged for sodium or hydrogen ions of the resin.

7. Thermal reduction: Thermal reduction requires burning and consequent oxidation of some toxic and refractive substances, like organic cyanide, which may be present in certain specific industrial waste waters.

8. Air stripping: In air stripping the liquid waste is poured down through a packed tower, equipped with an air blower at the bottom. This is a modification of aeration- process, used for removal of gases from the waste water.

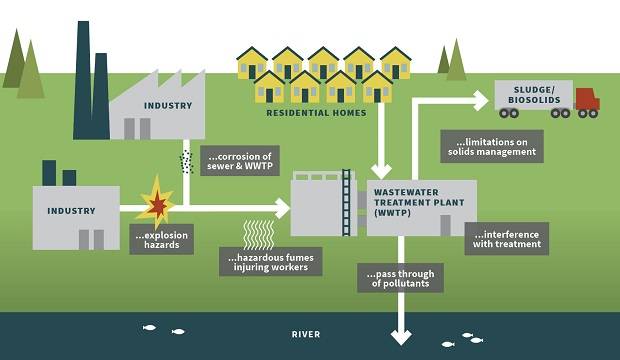

Discuss the effects of industrial effluent disposal on sewers, treatment plants and receiving streams.

Heavier suspended solids deposit in sewers or in receiving streams and cause choking troubles.

They may also smoother the fish life in streams. Greasy and oily material induces deposition at above places, causes skimming troubles at the treatment plants and ugly scums and sludge banks in receiving waters.

They also interfere with the rights of riparian owners, and with the natural reaeration inducing septicity.

Acidic and corrosive discharges act upon the sewer materials and the treatment plant structures and equipment corroding and weakening them and also reduce their useful life and capacities.

These along with the toxic metals and chemicals destroy the biological activity in streams and municipal sewage treatment plants and render receiving waters unfit for further use. Higher temperature of wastes will aggrevate the situation by hastening the chemical and biological reactions.

Also, Read This.