The term P.C.C. stands for plain Cement Concrete work procedure. Before starting any R.C.C. or masonry work directly on the excavated soil, P.C.C. is done to form a leveled surface.

- P.C.C. is done on the excavated soil strata or on soling provided.

- Unless specified, a volumetric mix proportion of 1:4:8 or 1:3:6 is normally used for P.C.C.

- P.C.C. mixing is generally a manual process.

BASIC REQUIREMENTS MATERIALS, PCC PLAIN CEMENT CONCRETE WORK PROCEDURE

The basic ingredients for P.C.C. are

- Cement

- Sand

- Coarse aggregates

- Water

1. CEMENT

Ordinary Portland Cement (O.P.C.) is normally used for P.C.C. It should conform to the specifications and tests outlined in Chapter.

2. SAND

Sand for concrete works should be clean, well-graded, hard, strong, durable, and should meet the requirements specified.

3. COARSE AGGREGATES

- The size of aggregates used for P.C.C. varies from 20mm to 25mm (3/4″ to 1″).

- As the maximum size of the aggregate is more, it results in the reduction of cement consumption.

- Coarse aggregates shall be clean and free from elongated, flaky, or laminated pieces.

- The coarse aggregates should be free from adhering coating, clay lumps, coal residue, clinkers, slag, alkali, mica, organic matter, or other substances.

4. WATER

Water required in plain cement concrete is 40 – 45%

TOOLS AND MACHINERIES REQUIRED PCC PLAIN CEMENT CONCRETE WORK

TOOLS

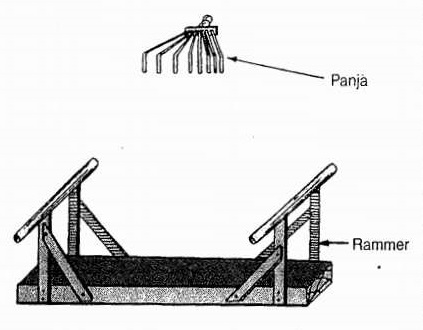

Spade, pans, buckets, mixing tray, panja, rammer, level tube, water storage drums, curing pipe, line dori, plumb, hammer, thapi, randha/tipani, measuring boxes (Farma), etc.

MACHINERIES

- Mixers (in the rare case)

- Needle vibrator (in the rare case)

- De-watering pump

PREPARATION FOR P.C.C. PLAIN CEMENT CONCRETE WORKS

- Check the center of the excavated pit.

- Check the dimensions and orientation of the excavated pit (length, breadth, and depth). Record the joint measurements.

- Get the strata checked and approved by the consultant.

- Clean the pit by removing all loose materials.

|

| the tool requires PCC work |

- Water the excavated pit and ram it for better-compacted strata.

- If the surface level of the pit is uneven, do the soling or plum concrete to avoid the excess depth of P.C.C.

- Prepare the shuttering box of P.C.C. size and place it in position.

- Get the required material stocked a day in advance.

- Get the cement checked and keep it ready for P.C.C. work.

- Keep all the tools and machinery ready by cleaning, washing, lubricating, etc.

Before PCC Work Done keep precautions? Tips for PCC Work in foundation.

WORK PROCEDURE FOR P.C.C. PLAIN CEMENT CONCRETE IN FOUNDATION

- After completing the preparations mentioned in 22.4, P.C.C. should be done. It includes batching, mixing, placing, and compacting. The procedure to be adopted is as follows.

- Prepare the volumetric depos of sand and metal on the mixing tray, by taking the specified proportionate quantities. It is advisable to dump depos required for half a bag for better & uniform mixing.

- Mix half a bag, at a time, with proportionate depo of the aggregates.

- Mix the dry depo thoroughly using a spade. Confirm that the cement, sand, and metal are uniformly mixed.

- Pour the required quantity of water in the above mixture, to maintain the water-cement ratio and to get workable concrete.

- Pour the concrete in place, using ghamelas (Mortar pans).

- Use panja for spreading and leveling of concrete.

- If the depth of the pit is more, one labour should receive the concrete in the pit and pour the concrete in position, to avoid segregation.

- The use of chute can also be made for placing concrete where the depth of the excavation is more.

- The concrete which is poured, can be compacted either by steel rammer or by a vibrator, depending upon the depth of the P.C.C.

- The sides of the shuttering should be tamped and finished with thapi to get a smooth and uniform finish after deshuttering.

- The top surface of the P.C.C. should be leveled and finished by randha

- or tipani to get a uniform finish.

CURING OF P.C.C PLAIN CEMENT CONCRETE.

- Curing of P.C.C. may be done by either pouring water with buckets or with a curing pipe.

- The centers of the respective columns are marked on the P.C.C. either by nailing or by using a cement mortar.

- Curing should be carried out for a minimum of 14 days.

DO’S AND DONT’S OF PLAIN CEMENT CONCRETE P.C.C. WORKS

DO’S

- Check and get the strata approved by the Structural Consultant before P.C.C.

- P.C.C. shuttering should be of the exact size and thickness.

- Dry depo should be uniformly mixed before adding water to it.

- Water should be mixed with a bucket, in a measured quantity, as per W/C ratio.

- Use the chute or additional labor to pour the concrete where the depth is more.

- Remove any loose material from the sides of the pit, so that no soil or other material will collapse in the pit during concreting.

- If the water table is high, de-watering should be carried out simultaneously during concreting.

- Compact and level the concrete properly.

- Maintain the levels of P.C.C.

- Mark the center of the column, the next day.

DONT’S

- Do not mix the depo on bare land.

- Do not mix the water in depo by means of a pipe.

- Do not allow the P.C.C. without formwork.

- Do not pour concrete without leveling and compacting.

- Do not pour concrete in the pit from a height of more than 1.5m.

- Do not allow extra cement mortar on top of P.C.C. for smooth finishing.

Also, Read This

It’s so educative,looking forward to get this task done to the actual ground soon enough , thanks alot,it’s the best guidance both to the new and already taught student or senior engineer.