TYPES OF STRUCTURAL GLAZING GLASS

- Obscured glass

- Plain glass

- Tinted glass

- Wired glass

Pinhead (Bajari), flora (tomato), chameli, and pyramid are the different varieties of obscured glass.

Bajari is the most popular and is commonly used for glazing.

2. PLAIN GLASS

Generally, plain glass is used for aluminium windows and M.S. windows.

It is available in thickness varying between 2mm to 19mm, like 2mm, 3mm, 4mm, 5mm, 5.5mm, 6mm, 8mm, 10mm, 12mm, 15mm, and 19mm.

It is completely transparent. A variety of plain glass is available. Both sides of the glass are plain and smooth.

It does not allow privacy unless specially treated.

Tinted glass is most often used for aluminum windows. It is available in the same thicknesses as lain glass. Privacy may be gained with this glass.

It is manufactured by rolling molten glass with a steel wire mesh that is embedded in it.

This glass is used in fire break doors and in roof glazing because the wire mesh holds the broken glass together and so minimizes the danger of the glass breaking into pieces.

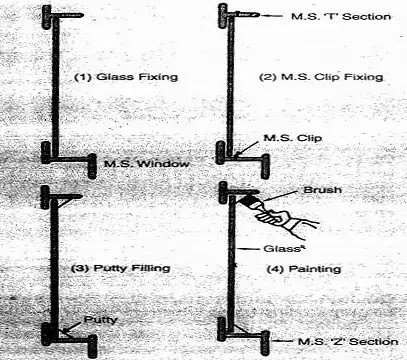

STRUCTURAL GLAZING WORK PROCEDURE – GLASS FIXING (BAJARI PLAIN) TO M.S. WINDOWS

- Check all the windows for its straightness and, bends, fixity, rigidity in fixing, etc.

- Before fixing the glass, ensure that all the work inside the flats is complete. A coat of distemper painting should also be completed to minimize the chances of breakage of glass.

- Ensure that the window is properly scraped, cleaned, and painted with a coat of oil paint.

- The measurements of glass panels should be taken at the site.

- Glasses are cut to the required size and brought to the site for fixing.

- Check the glass for thickness and quality as per the ordered specifications.

- Check the glazing clips and putty (lambi) for quality and brand.

- Glass is fixed in the panels from outside, with the help of a ladder or zula for external windows.

- Glass panes should be perfectly cut to match the size of each panel. Ensure that the fitting is not loose.

- Cut the glass using a glass cutter with a diamond point.

- M.S. clips are fixed to support the glass in T/Z section.

- See that clips are fixed in every hole.

- Apply putty to the corners of the panels. The quality of the putty is important. The roll should be prepared by using whiting to get a consistent uncracked filling.

- The putty should cover the M.S. clip.

- Cut the putty at an angle, i.e., about 45 degrees to glass.

- Smooth the surface of the putty with a cut piece of glass.

- After the putty is dry, the final coat of oil paint should be given.

- Clean the window glasses with wet dusters paper to remove paint stains.

- Generally, plain glass is used for aluminum windows.

- Check the tracks of aluminum window for its level straightness, the width of the track, the smoothness of the track, etc.

- Cut the glass as per the required size.

|

| PROCEDURE OF GLASS FIXING FOR M.S WINDOWS |

- Provide rubber packing strips on the edges of the glass and prepare the panel to fix in the track.

- The required size of the glass should be less by 2 mm than the size of the panel.

- Fix the panels on track and check it for free movement. It should not shake considerably and prepare the panels to fix in the track. across the track.

- Clean the glass with a cloth or paper.

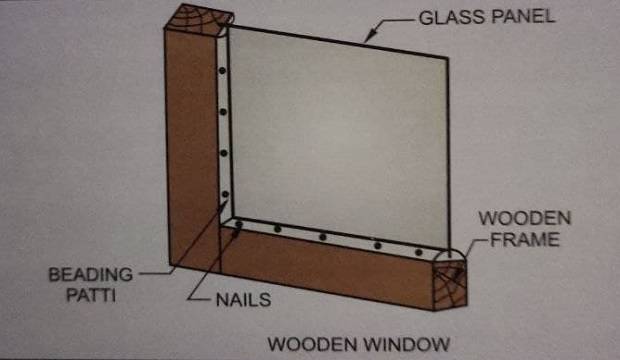

HOW TO FIXING STRUCTURAL GLAZING GLASS

- Ensure that one coat of oil paint is applied to the wooden window.

- Measurements should be taken on-site.

- Fix the M.S. grill, if any, before fixing the glass panel and two coats of oil paint.

- Ensure that the beading patti on one side of the panel is applied rigidly (on which M.S. grill is fixed) and keep the other side of the beading patti loose.

- Remove all the loose beading pattis.

- Fix the glass panel in the space touching the other side of the fixed beading pattis.

- Then fix the beading patti on the other side carefully with panel pins to prevent the glass from breaking.

- Clean the glass with cloth paper.

3. STRUCTURAL GLAZING PUTTY (LAMBI)

Glass is fitted to the window with putty. It ensures that the glass remains in position. Putty is made by mixing one part of white lead to three parts of finely powdered chalk. boiled linseed oil is added to this mixture to form a stiff paste of the desired consistency. Readymade putty is easily available in the market under the brand names Brite, Shalimar, Kumb, etc.

Following precautions should be taken while or using putty for glass fixing

- Mix the putty at the site with linseed oil and form a roll for better consistency.

- Ensure that the second coat of oil paint is applied after the putty is in a semi-dry condition.

- The finishing of the putty should be made smooth with a glass cut piece.

- Ensure that a sufficient quantity of putty is applied to every panel.

- Before applying putty, ensure that glazing clips are fixed in every hole provided in the frame.

- The position and tension of each glazing clip should enable holding the glass in position.

- Ensure that the glass size is not undercut.

- Use a glass diamond cutter to cut the glass of the required size.

- Do not disturb the glass panes when the putty is wet.

Glass is manufactured in standard sizes of sheets. As per the requirement of window panels, the glass has to be fixed. This causes the wastage of glass.

The actual size of glass for window panel

40cm (16″) x 55cm (22″)

70cm x (28″) x 65cm (26″)

Actual payment to be made.

45cm (18″) x 60cm (24″)

75cm (30″) x 75cm (30″)

Also, Read This

Is Vinyl a Good Choice for Door and Window Frames?