Bearings in bridges are provided in bridges to transmit the load from the superstructure to the substructure in such a manner that the bearing stresses induced in the substructure are within permissible limits.

They should also accommodate certain relative movements between the superstructure and the substructure.

The latter are usually due to one or more of the following:

(a) longitudinal movement due to temperature variation

(b) rotation due to deflection of the girders; and

(c) vertical movement due to the sinking of the supports.

In addition, there can be movements due to shrinkage, prestressing or creep. The movement and rotations may be reversible or irreversible.

The reversible effects are usually cyclic and are due to temperature changes and live loads.

Effects due to settlement of supports, prestressing, creep or shrinkage are irreversible.

The magnitude of thermal movement depends on the coefficient of linear expansion and the temperature range to which the member is subjected.

For the purpose of preliminary estimates, the maximum range of movement due to all causes, expressed as a proportion of the expansion length, may be assumed as below :

In-situ reinforced concrete 0.0009

Precast reinforced concrete 0.0007

In-situ prestressed concrete 0.0016

Precast prestressed concrete 0.0011

Steel 0.0009

Composite steel and concrete 0.0008

The end rotation of a beam of the uniform section may be estimated for initial assessments as four times the maximum permissible midspan deflection divided by the span.

What are the different types of Expansion bearings for girder bridges? State the circumstances under which each would be appropriate.

Girder bridges should be provided with fixed and expansion joints. Fixed bearings should have provision for rotation and expansion bearings should be able to allow longitudinal movements as well as rotation.

During construction, expansion bearings should be properly aligned to correct for the temperature prevailing at the time of erection. For

bridges in gradient, the bearing plates are to be placed in a horizontal plane.

In seismic areas, suitable guides should be incorporated in the bearings to prevent the roller and rocker from being displaced during earthquakes.

For skew bridges with a skew angle less than 20 degrees, the metallic bearings to be provided are placed at right angles to the longitudinal axis of the bridge.

When the skew angle is more than 20 degrees ad the span length along the longitudinal axis is less u than m, an arrangement for sliding should be made at both supports. If the span length exceeds 10 m, the fixed bearing is provided at the obtuse comer of the bridge.

Since the axis of rotation and the direction of longitudinal movement are not perpendicular, the fixed bearing should be capable of allowing rotation in any direction, and the free bearing should allow movement and rotation in any direction.

In the case of curved bridges bearings that allow movement and rotation in any direction are used.

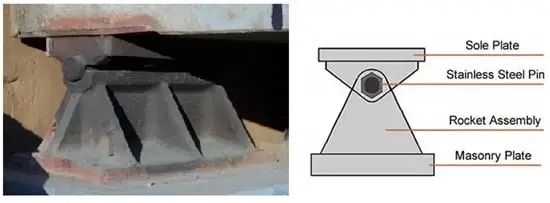

Expansion bearings for girder bridges are of the following types :

1. Sliding plate bearing

2. Sliding-cum-rocker bearing

3. Steel roller-cum-rocker bearing

4. R.C. rocker expansion bearing

What are the considerations for the design of an elastomeric bearing for a girder bridge?

The dimensioning of the bearing and the number of internal layers of elastomer chosen are arranged in such a manner that the following design criteria are satisfied:

1. The plan dimensions shall conform to ‘preferred numbers’ R’20 series of IS: 1076, e.g., 10, 12, 14, 16, 18, 20, 22, 25, 28, 32, 36, 40, 45, 50, 56, 63, 71, 80, 90, 100 cm.

2. The effective area of the bearing (equal to the plan area of the laminate) should be adequate such that the average normal stress is less than the permissible contact pressure for the concrete structure

3. The ratio of overall length to breadth is equal to or less than 2.

4. The total elastomer thickness is between one-fifth and one-tenth of the overall breadth of the bearing.

5. Translation: The thickness of the elastomer in the bearing should be adequate to restrict the shear strain due to horizontal load and horizontal movement due to creep, shrinkage, and temperature to a value less than 0.7. In the absence of a more accurate analysis, the longitudinal translation due to creep, shrinkage, and temperature can be

computed assuming a total longitudinal strain of 5 x 10 for common R.C. bridge decks. The shear modulus of the elastomer is assumed as 1 N/mm., [1RC : 83 permits the value of shear modulus to be between 0.8 N/mm, and 1.2 N/mm ]

6. The thickness of an internal layer of elastomer h,, the thickness of a laminate hs, and the elastomer cover at top and at bottom h, are related as below

7. The side cover of the elastomer for the steel laminates is 6 mm on all sides.

8. The shape factor S is between 6 and 12.

What are the advantages of Elastomeric Bearing over the other type of Bearing?

Since metallic bearings are expansive in first cost and maintenance, the recent trend is to favour elastomeric bearings.

An elastomeric bearing accommodates both rotation and translation through deformation of the elastomeric.

These bearings are easy to install, low in the first cost, and require practically no maintenance. They do not freeze, corrode or deteriorate.

Barring an earthquake, the only probable causes for failure of an elastomeric bearing are inferior materials, incorrect design or improper installation.

Elastomeric bearings are ‘forgiving’ in that they can tolerate loads and movements exceeding the design values.

What are the various causes of reconstruction?

The main causes of reconstruction include:

(a) inadequate carriageway for the volume of traffic;

(b) structural inadequacy due to deterioration or increase in design loadings;

(c) insufficient waterway for river bridges and

(d) inadequate clearances for roads under bridges.

What the difference between the expansion and contraction Joint?

Expansion joints and contraction joints are provided to take care of deformations due to changes in temperature.

The difference between the two types is in the depth of the joint and also in the width, Contraction joints, where provided, will be only for a part of the depth of the slab and will often be of smaller width.

Expansion joints will be the full depth of the member.

What is the role of providing a construction joint?

Construction joint is necessary whenever the placement of concrete has to be stopped temporarily before the completion of the entire monolithic portion under construction.

Such temporary suspension of concrete placement may sometimes be unexpected, if it is due to failure of machinery such as concrete mixer, vibrator, etc. But often, it may be scheduled to facilitate the addition of reinforcements for a top portion, as in the case of the stem of a retaining wall.

When foundations of adjacent parts of the structure are at different levels, as in the case of the junction between the abutment and the wing wall, a construction joint should be provided.

What does Quality Assurance Include?

Quality Assurance (QA) includes all those planned actions necessary to provide adequate confidence that the product (in this case, the bridge) will meet the requirements, and is essentially a system of planning, organizing and controlling human skills to assure quality.

Quality Control (QC) deals with operational techniques of controlling quality.

Bridge Bearings in Hindi || Types of Bearings in Bridges || Bridge Engineering

Also, Read This