Advantages of asbestos pipes

1. They are light and hence easy to transport.

2. They can be easily assembled without skilled labour

3. They are highly flexible and may permit as much as 12-degree deflection in laying them around curves

4. Expansion joints are not required as the coefficient of expansion is low and the joints are also flexible

5. They are very smooth and are hydraulically efficient pipes. Their carrying capacity do not reduce with time

6. They are suitable for small size distribution pipes.

Disadvantages of asbestos pipes:

1. They are costly

2. These pipes do not have much strength and are brittle and soft. They are liable to get damaged by excavating tools or during transportation transit.

3. The rubber joint seal may deteriorate if exposed to gasoline or other petroleum products, and hence cannot be used for transporting petroleum products.

Write a short notes on steel pipes

Steel pipes are occasionally used for mainline and at such places where pressures are high and pipe diameter is more. These are more strong, have lightweight, and can withstand high pressure than cast iron pipes.

They are cheap, easy to construct, and can be easily transported. The disadvantage of these pipes is that they cannot withstand external loads.

If a partial vacuum is created by emptying a pipe rapidly, the pipe may be collapsed or be distorted.

These are affected by corrosion and are costly to maintain. The life of these pipes is 25 to 50 years. These are not used in the distribution systems, owing to the difficulty in making connections.

The joints are made by welding or riveting. Longitudinal lap joints are made in riveted steel pipes up to 120 cm in diameter. In case the thickness of the steel plate exceeds 15.87mm butt joints are provided.

If the diameter of the pipe is very large, two longitudinal seams may be provided. Welded steel pipes can be used for large diameters up to 2.43m or even more.

Uses of Hummed & Asbestos Pipes|Civil Engineering|water supply| sanitary Engineering|RCC pipe Joints

Name various types of sanitary fittings

In buildings, various types of sanitary fittings are required to collect the wastewater.

These all fittings can be broadly classified as:

A. Ablution fittings

1. Wash

2. Sinks

3. Bath tubs

4. Flushing cisterns

5. Drinking fountains

B. Soil Fittings

1. Water closets

2. Urinals

3. Slop

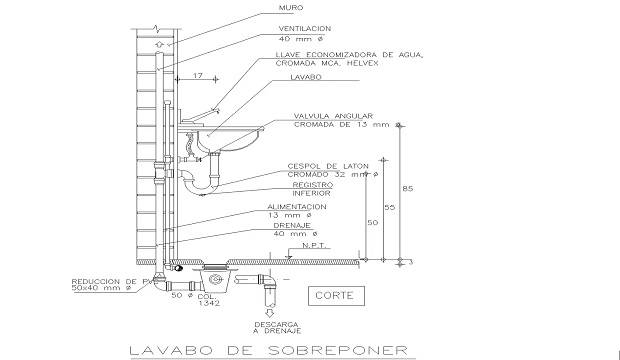

Write short notes on wash basins

Wash basins or lavatory basin is made of white glazed earthen ware, enameled iron, etc, these are of two types-the Flat Back and the Angled Back.

Wash basins are either fixed on brackets secured into the wall or on pedestals rising from the floor.

As shown the flat back has an oval-shaped bowl with a usual capacity of 5 liters up to the overflow, and a waste pipe of 32mm bore with a trap in the center. The waste opening is protected by a metallic strainer.

The overflow may be of an open weir type with a removable grating or of the slot type as shown in fig. there are two inlets, one for cold water usually on the right side of the user-facing the fixture, and the other for hot water.

These inlets are controlled by chromium-plated pillar taps. The wash when fixed has a height of 75 to 80 cm.

With the help of a neat sketch describe flushing cisterns

This is an appliance used for flushing out water closets, urinals, etc. These are of two types- the valveless siphonic type and the valve fitted siphonic type. The former is preferred and used in practice.

The Bell-type flushing cistern is a valve-less siphonic type. It consists of a cistern made of cast iron or pressed steel, having a suitable cover with a sump formed in the center through which the flush pipe of 32mm bore passes.

The flush pipe’s upper end is projected a little above the maximum water level in the cistern, while its lower end discharges into the W.C. pan. The flush pipe is covered up in the cistern by a C.1. bell to the top of which a lever arm with a chain is attached.

On pulling the chain the bell is lifted and on releasing it, it is lowered to its original position. Due to the movement, the water enclosed is spilled over the top of the flushing pipe, causing siphonic action and thereby emptying the entire contents of the cisterns.

Water now enters the cistern, the flow being controlled by a ball valve arrangement operated by a float. An overflow pipe is provided as an additional safeguard against overflowing in case the ball valve arrangement ceases to function.

What are traps, discuss different types of traps?

Types of traps are fittings placed in drainage pipes, which prevent the passage of foul air or gases through drains, waste or soil pipes and thus prevent their entry into the interior of houses or buildings.

Traps may be classified in two ways:

According to their shape as

1. P-trap

2. Q-trap

3. S-trap

According to their use

- Floor Trap

- Gully Trap

- Intercepting Trap

1. Floor traps: These are used for admitting waste water from floors of baths and kitchens. These are provided with cast iron grating at the top to exclude coarse solid matter, so as to prevent it from passing into the drain along with the wastewater and thereby cause blockade. A form of floor trap much used in practice is the Nahni

trap.

2. Gully trap: These are used for the reception of sullage from baths, sinks, and wash basins as well as rain or surface water from housetops and back yards.

The waste pipes or the rain waste pipes, discharging into drains, are seldom connected to them without such interception.

A Gully trap may have P-trap or S-trap. The water seal is 50 to 75mm deep. The upper section of the trap is covered by a C.l.grating to exclude coarse or solid matter.

3. Intercepting traps, or Interceptors: These are used at the junction of the house drain and the house sewer with the primary objective of preventing the foul gases in the public sewer from entering the house drainage system.

These gases are led off through ventilating columns which are provided at the head of every branch sewer and at key positions in the sewerage systems.

The trap has an opening at the top called the ‘cleaning eye’ or ‘rodding arm’ and has a tight-fitting plug. This enables the trap to be periodically cleaned of any obstruction present inside. The water seal is 75mm deep.

Write short notes on sinks and urinals

Sinks: It is a rectangular receptacle used in the kitchen or laboratory for draining off water. It is commonly made of glazed earthenware.

The usual size is 60cm*45cm*25cm, the sink is provided with a wooden draining board fixed on the right of the user. It should be so located as to directly receive light through the window.

The height from the floor to the top edge of the sink is about 90cm. Urinals; These are usually of two types- the Bowl type and the Slab or Stall type.

The bowl-type has a lipped basin with a flushing rim while the slab or staltype comprises of flat wall slab with partitions on the sides and a floor channel to drain off the discharge through a trapped outlet.

Both the types are flushed through a siphonic type of flushing cisterns; in the bowl type the cistern may be hand-operated and of 5 liters capacity while in the stall type, an automatic flushing cistern with a capacity of 10 to 15 liters feeds a range of three or more stall urinals.

What are the principle governing the design of water supply in buildings?

The principle governing the design of water supply in buildings are There should be absolutely no risk involved in the contamination of water supply for domestic purposes.

In order to ensure this three things are necessary, There should not be any cross-connection anywhere between a pipe containing potable water and a pipe containing used or polluted water b. There should be no backflow from any cistern or appliance toward the source of supply.

An adequate air gap, at least 15cm between the outlet end of the supply pipe discharging water into the cistern and its flood level rim effectively prevents any occurrence of backflow C.

The water supply and the drainage pipes should not be laid very close to each other. The pipes and fittings should be thoroughly water-tight in order to protect the building against possible damage due to leakage.

Water tightness of joints ensures minimum wastage of water and the risk of contamination is also considerably reduced

The pipework should be amply protected against any possible damage. When laid underground, as in the case of service pipe, it should have an earth cover of at least 60cm,

when laid above the ground or in exposed situations, it should run clear of the wall with a clearance of 2.5 cm and when crossing wall or floor it should be contained in suitable sleeves for the entire length.

Water supply pipes should carry water inside the building under adequate pressure in the water main. However, where available pressure are insufficient and it becomes necessary to pump water, as in the case of multi-storeyed buildings separate storage tanks may be used for providing the necessary suction lift.

The booster pumps if used, should not be allowed in the service pipe as its suction lift decreases the pressure of water supply to the adjoining building.