(1) Market survey for new materials and development of new supply sources.

(2) Vendor development.

(3) Follow up to ensure proper delivery.

OBJECTIVES AND SCOPE- PURCHASE DEPARTMENT PROCEDURE BUILDING

The principal objective of the purchase department can be summarized as the procurement of materials of the best quality, inaccurate quantities, and at the right time from the right supplier for the correct price.

To elaborate, the major objectives of the purchase department procedure are

- Maintaining continuity of supply of materials required for construction purposes.

- Maintaining standards in the quality of material supply.

- Developing good reliable suppliers and ensuring satisfactory vendor relations.

- Keep the Directors/top management abreast of the materials’ development that would affect the company’s profit.

- Control the total inventory on-site.

- Study of proper materials utilization at the site.

PURCHASE DEPARTMENT PROCEDURE BUILDING CONSTRUCTION

- Before starting a new project, specifications of all materials should be finalized and the requisition accepted accordingly.

- If the specifications are altered by the management or due to the non-availability of the materials, the same should be intimated to the purchase department, engineering department, and the respective site.

- The functional procedures followed by the purchase department building are as follows.

- Acceptance of requisitions

- Issuing of purchase order

- Pending requisitions

- Site visits

- Reporting

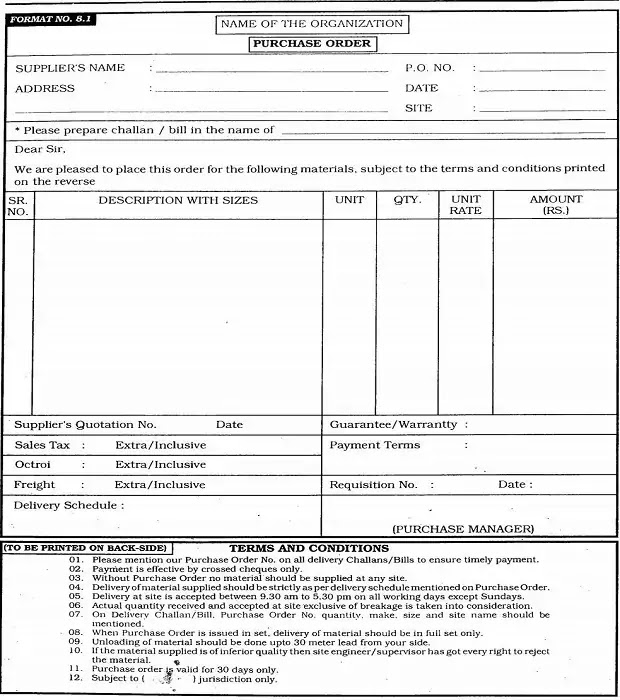

- A purchase order is a printed format in triplicate copies of different colors. Separate order should be issued for each requisition and material.

- The first copy is to be given to the supplier, the second should be sent to the accounts department for clearing the bills and the third copy is to be kept in the purchasing department for record purposes.

- The purchase order should be clear in the specification, rates, units, all types of taxes, insurance, excise, delivery date, credit date, and mode of measurements and payments with printed terms and conditions on the backside (refer specimen purchase order.

- As per the specification and requirements of the requisition, a purchase order should be issued for each supplier and the purchasing department must deliver the material in time and at the right place.

The storekeeper will inspect the material received at the site for quality as per the specifications. If he is satisfied, the material will be unloaded in the store/ at any other required place. Otherwise, he must inform his superiors.

They will then inspect the material to discuss the discrepancies regarding quality with the Purchase Manager. As per the instructions of the Purchase Manager the material may be accepted or rejected.

The engineers should submít quality reports of all the major materials received on site.

Here are some quick checkpoints

- Is this the correct/specified type of material?

- Is this the exact color required?

- Check all dimensions for the correct size.

- Inspect all visible areas for damage.

- Is the order complete? Any item back-ordered should be placed on the ALERT list for immediate follow-up.

- Absorptive materials such as wood or cement should be checked to see that they are not dampened.

- Are the materials being stored nearest to the point of use?

- Will the materials be safe from weather, damage, theft, or other hazards?

- Are they placed for easy handling and movement, if required?

- If the materials are not received as per requisition, then the senior engineer must prepare the pending requisition, giving full details of the materials required.

- The Project Engineer will highlight the materials required urgently on the site and submit the list to the purchase department through Chief Engineer every fortnight.

- This will help the purchasing department in following up with the supplier and deliver the pending materials.

The Purchase Managers should visit the site every week to check the quality of the material received, unutilized excess material on-site and to control the inventory and stacking of materials. A joint visit with the supplier will solve any disputes of quality.

- The Purchase Manager should submit a monthly report with full details of the materials purchased, material replaced if any material rejections/replacements, problems (if any) from site or supplier.

- He should also study the price hike with the help of graphs.

- At the end of every year, the Purchase Manager should collect a list of targeted materials required for the coming year from the Chief Engineer.

- This is useful for planning as specified below.

- To purchase materials, directly from manufacturers, companies, or distributors only.

- Proper planning of major materials.

- Seasonal purchase (if any)

- Inventory control on site

- To avoid panic purchase i.e. last-minute purchase

- To increase source and suppliers

- Computerization of the department

SUPPLIER’S LISTING

Every year, depending on the performance, capacity, reliability, commitment, etc. a list of suppliers should be updated. The first preference should be given to ‘A grade suppliers. In case of non-availability of materials, the order should be placed to the ‘B’ grade supplier.

In the case of fluctuating market rates, the Purchase Manager should call for quotations. A comparison should be made and the purchase order placed accordingly.

A typical specimen comparison for three suppliers is illustrated for reference.

Rates of AB & Co. are very high whereas the rate of EF & Co. is a bit low, considering the octroi and transportation charges. CD & Co.’s rates are a little on the higher side. Considering his capacity. reliability, commitment, credit days, and the relations with the company, a purchase order should be placed to CD & Co.

A short-term or long-term contract should be entered into for bulk purchases of major materials so as to obtain a maximum benefit on the rate.

ROLES AND RESPONSIBILITIES OF PURCHASE MANAGER

The purchase Manager should maintain a directory of approved suppliers containing the following data

- Name of supplier

- Address

- Telephone, fax, telex number, etc.

- Supplier’s status i.e. manufacturer/ distributor/ dealer/ retailer

- Contact person’s name

- Reference is given by

- List of available materials

- The purchase Manager is authorized to sign the purchase order.

- If the supplier fails to supply the materials within the specified time, as mentioned in the delivery schedule, the same order can be placed on another supplier and the first order can be canceled or withheld.

- The Purchase Manager is responsible for the quality of the material supplied.

- Inventory control of materials at the site should be controlled partially by the Purchase Manager.

- The purchase Manager should have complete knowledge of the availability of materials in the market.

- He should be present at the time of finalizing the specifications of the buildings by the technical department.

- Management should give the Purchase Manager a free hand in dealing with the suppliers and his decision-making authority should be clear.

- The Purchase Manager should be aware of the new products coming in the market along with the technical know-how.

- He should have updated information on market rates. He should go through various publications and attend seminars. This is useful for updating the knowledge for vendor development.

|

| Purchase order |